Box Printing Explained; Find Out The Best Method For Your Packaging Project

We’re here to help you unleash your brands potential with our box printing expertise. When deciding on how to print your packaging, we will discuss many factors with you, such as:

- Artwork Design

- Desired Finish

- Budget

- Packaging Design

- Packaging Application

- Production Run Size

Our custom packaging experts are always on hand with advice, but let’s explore 3 of the most popular techniques used for printing packaging in the UK today:

1. Digital Printing

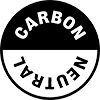

We’ve seen a huge increase in the popularity of digital printing across a wide range of packaging products, including retail packaging, eCommerce packaging and food packaging.

With a fast turnaround and no set up costs, this is an excellent choice for small – medium runs, seasonal packaging and packaging for small businesses or start-ups.

Printing Substrates:

Corrugated packaging, folding cartons, cardboard sleeves, rigid paper covered boxes, paper bags, stickers.

Pro’s:

No set up costs. Produces high quality detailed print. Cost effective on small to medium production runs. Low minimums. Fast turnaround. Matt or gloss varnishes. Variable print options within the same run.

Con’s:

Only uses CMYK and therefore cannot colour match to pantones. Unit costs can rack up on large production runs, so best to use litho for high volume jobs of over 20,000 unit’s, to get the most competitive prices.

Eco Roundup:

A sustainable option that uses less energy and produces less waste. Water based inks are commonly used and harmful chemicals avoided. Packaging can be recycled after use.

2. Lithographic Printing

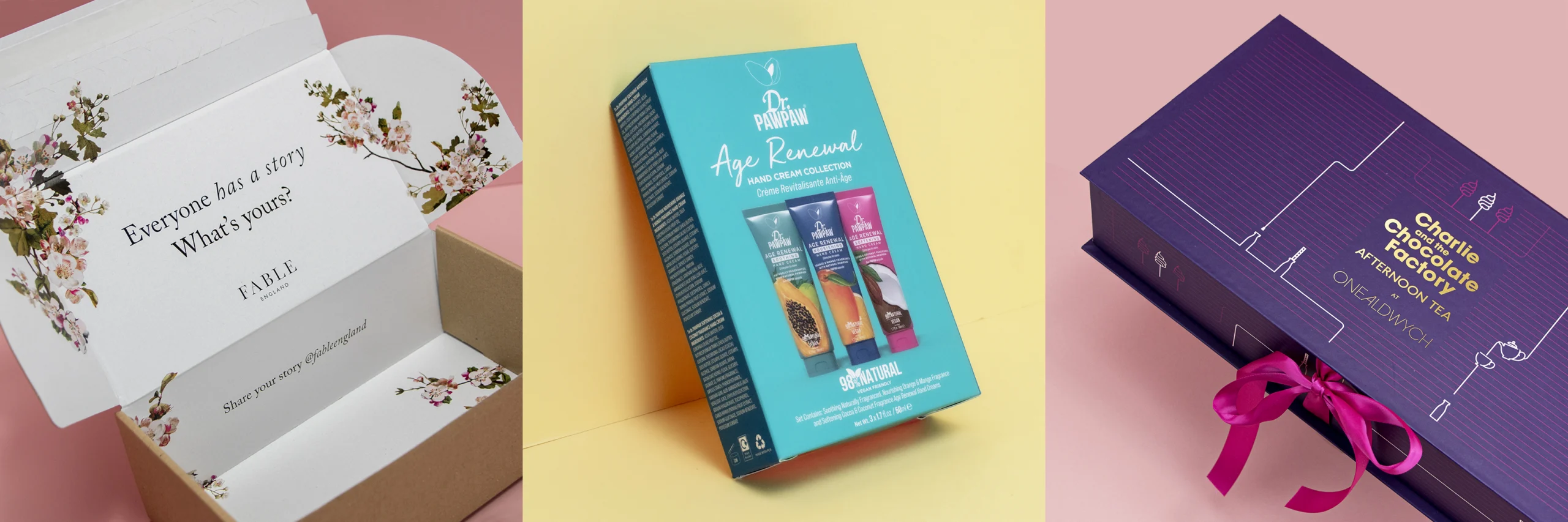

Litho printing is a firm favorite for brands going into retail, providing a classic and sophisticated look to any packaging. Best suited to high volume production runs, litho printing is perfect for cosmetics, food and drink, pharmaceuticals, and gifts.

Printing Substrates:

Corrugated packaging, folding cartons, rigid paper covered boxes, paper bags.

Pro’s:

Produces a high-quality, detailed print. Flexible speciality finishes can be applied. Excellent colour matching. Cost effective for large production runs (20,000 unit’s and over).

Con’s:

High unit cost for small production runs. Lead times can be slightly longer than flexo or digital printing. No variable print options (available with digital).

Eco Roundup:

Suitable for use on recycled cardboard materials, although opting for lamination instead of varnish will make it more difficult for the packaging to be recycled after use. Generally uses eco-friendly water or vegetable based inks. Although litho printing uses more energy than digital printing, it is more environmentally efficient for long-run printing due to the economies of scale. Packaging is easy to recycle, unless laminated.

3. Flexographic Printing

Flexographic printing remains a popular, cost-effective choice, for many types of corrugated packaging;

Shipping Boxes

Shipping boxes are efficiently printed with logos, bar codes and product information, promoting brand awareness and easy identification.

Postal Boxes

We’ve seen an incline in the popularity of branded postal packaging with clients opting for either flexo or digital printing. Recently trending has been the use of printed messages on the inside of the box, helping to build connections and leave lasting impressions with customers.

Pizza Boxes & Takeaway Bags

Food outlets can keep costs to a minimum by opting for 1-2 colour flexo printed pizza boxes and takeaway bags.

Flexographic printing does however have its limitations, so It’s a good idea to read our blog on ‘Making the most of your flexo printed packaging’.

Printing Substrates:

Corrugated packaging, paper bags, paper tape

Pro’s:

Cost effective unit costs. Good definition. Suitable for both small or large runs.

Con’s:

Set up costs for printing plates, so not suitable for small one-off runs. Only matt finish available.

Limitations with complicated or extensive artwork compared to digital or litho printing.

Eco Roundup:

Flexographic printing is a great environmentally friendly choice, as it allows for the use of more sustainable and recycled materials. Water based inks are on the rise with solvent-based inks declining. Your packaging is easily recycled or composted after use.