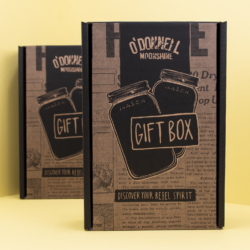

Flexographic packaging helps you shout loud and clear about what your company does and why consumers should buy your product. If you’re a smaller business on a budget, flexo printing is ideal for small to medium printing runs without compromising print definition or quality.

Relay important information to your customers such as “this way up” or show couriers that your products are fragile and delicate. With low-set up costs and efficient run times, flexographic printing can revolutionise your packaging operation.

Flexographic printing is an excellent choice if your design is logo or text-based. You can go down the minimalist route by adding a product reference or a simple instruction, such as “fragile” or “handle with care”, or you can print the entire box with your chosen colours. You can enjoy detailed, high-definition graphics using up to five individual colours, which is beneficial for larger print runs.

Which Materials Can Be Flexo Printed?

Flexographic print can be applied to all kinds of cardboard boxes and paper bags.

Our Expertise

Packaging Supplies is certified by the British Reputation Compliance Global Standards (BRCGS) to store food-grade and non-food-grade packaging. All the materials we use are safe, sanitary and sustainable. We can help you create your packaging artwork design and layout, providing PDF artwork proofs to make sure you’re happy before presenting the finished product. Our team is your team and we’re detail-oriented — we can even send ink swatches to ensure colour consistency in your packaging.

Interested in printed packaging? Give us a call on 01491 736238 or use the enquiry form