This page is to aid you in board and material selection and the different styles that are available, educating our customer base is all part of our value added service. Get in touch for more information.

Corrugated board boxes and folding box board cartons can be made in a variety of grades to suit the application required. With our expertise, we can guide you to the most appropriate type of box board for your product and requirements.

Corrugated board is available in many different grades and profiles. The grades vary from a completely recycled material to a virgin Kraft material and are available in wide range of grammages.

Kraft paper, recycled paper fluting and test recycled inner liners are the most common material make up of a corrugated box. Kraft paper on the outside; these have higher levels of virgin sustainably sourced paper (non-recycled), which gives a higher quality of finish, strength and a better printing surface ideal for custom cardboard boxes.

White paper can be used as the external liner paper for your box, it can be a cost-effective way to give you a higher end feel to your corrugated box. White paper gives a nicer finish and is a superior substrate leading to better print quality.

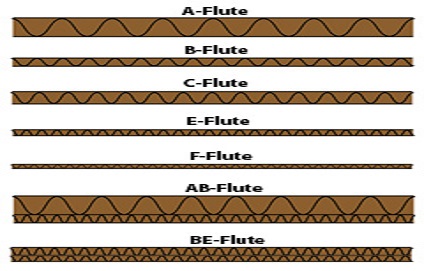

Standard paper thickness start at 125gsm (gram per square meter) and moves up through 150, 200 and on up to 300 gsm. Extreme Heavy Duty Corrugated cases & boxes using up to 1000gsm liners can, where required, be supplied. The strength of the box is affected not only by the paper thickness but also by the grade of fluting you have. Fluting is explained more fully below.

The standard most common flute profiles that we work with are classified by their height as E, B, C, BC and EB, there are also numerous much thinner micro flutings available. See further information and diagrams below:

C-Flute

Folding box board is a paperboard substrate made up of multiple layers of chemical and mechanical pulp. The top layer is a bleached chemical pulp with an optional pigment coating added. This is a low-density material with good rigidity, great printability and can be structurally designed into a range of shapes and configurations.

Folding cartons or box board boxes can also be made from a Kraftpakå¨ board which is an unbleached, uncoated, high strength board. Kraftpakå¨ has excellent wet strength capabilities, making it suitable for food and beverage packaging.

Coloured, metalized, textured and pearlized boards are also available for making specialist folding cartons.

The material used allows many design features and structures to become possible. Folding cartons are used to produce a huge variety of custom boxes, gift, retail cartons and sleeves.

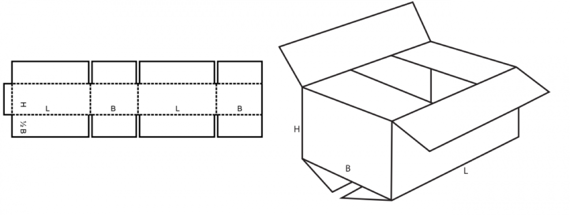

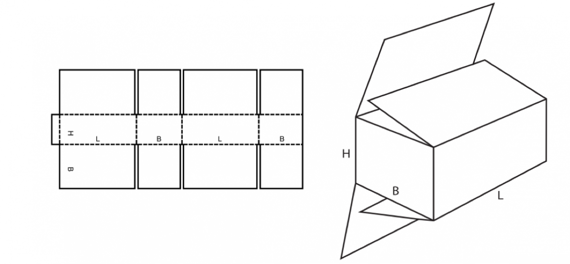

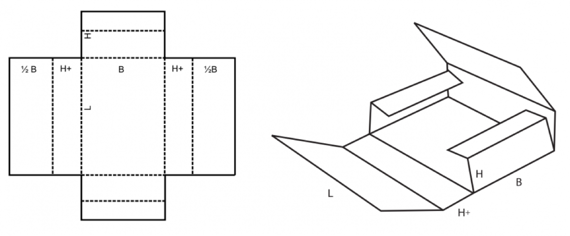

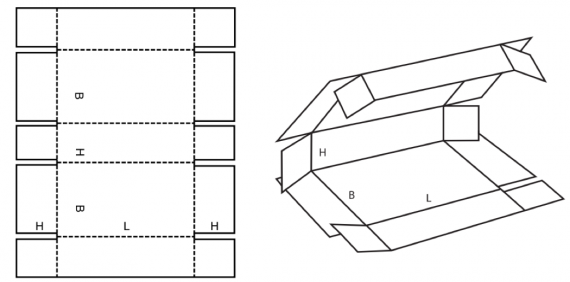

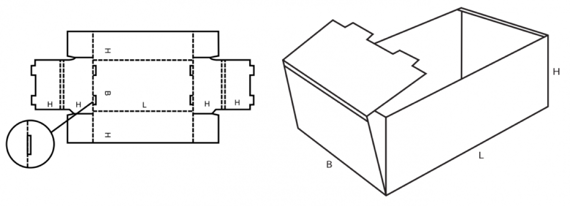

The European Federation of Corrugated Board Manufacturers (FEFCO) and the European Solid board Organisation (ESBO) is an official system which has been developed to standardise and list certain common pack designs. This avoids over complicated verbal descriptions of fibreboard case and packaging constructions and replaces them with simple symbols, internationally understood by all, regardless of language and other differences. The most popular styles include:

The latest edition of the FEFCO / ESBO list can be downloaded in a pdf format.