Types of Board Materials

Let’s explore a variety of board packaging types that cater to diverse needs and applications. From corrugated board for robust protection to solid board for elegant presentation and folding cartons for convenient storage, we’ll get into the characteristics, benefits, and ideal uses of each type.

-

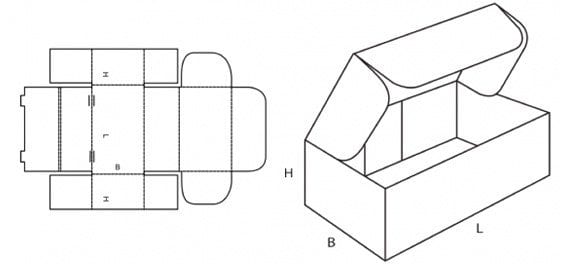

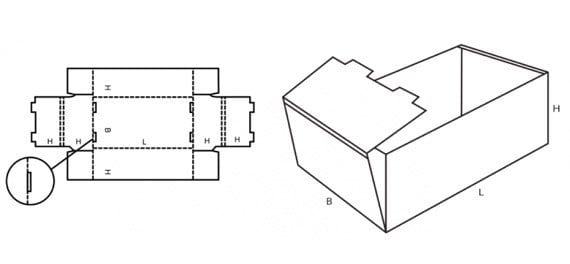

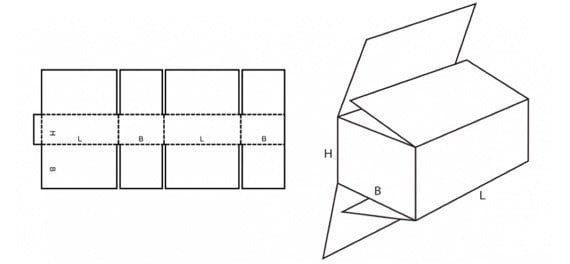

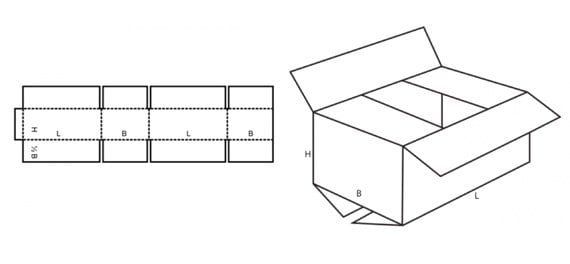

FEFCO Corrugated Packaging

FEFCO corrugated packaging board offers a wide selection of grades and profiles, ranging from recycled materials to virgin Kraft. With varying grammages available, you can choose from a range of FEFCO box styles to suit your specific packaging needs.

-

Kraft/Test Paper and Fluting

Kraft paper, recycled paper fluting, and test recycled inner liners are the primary materials used in the production of corrugated boxes. The outer layer is lined with Kraft paper, which boasts a superior quality finish, enhanced strength, and an excellent printing surface. Our Kraft paper is sourced from sustainable virgin paper, providing optimal performance for custom corrugated boxes. We also use Kraft paper in our food packaging, as it’s recyclable and meets food-grade standards.

Using white paper as the external liner of your corrugated box offers a cost-effective solution. Using a premium aesthetic white paper delivers a refined finish and enhances print quality and makes your custom packaging designs stand out. The standard paper thickness ranges from 125gsm to 300gsm, while heavy-duty cases and boxes can be supplied with liners up to 1000gsm when necessary. It’s important to note that the strength of the box is influenced by both the paper thickness and the chosen fluting grade.

-

Corrugated Packaging Fluting

Corrugated boxes come in three main types of fluting:

- Single Face – a one-liner board and one fluted medium.

- Single Wall – two liner boards and one fluted medium.

- Double Wall – three liner boards and two fluted mediums.

Single Wall is the most common type of fluting as it offers strength and durability while remaining cost-effective. Double Wall fluting is the strongest option and provides robust protection for heavy or fragile items. Single Face fluting provides minimal cushioning, yet is highly cost-effective.

We also offer thinner micro flutings — contact us to find out more about the options we have available.

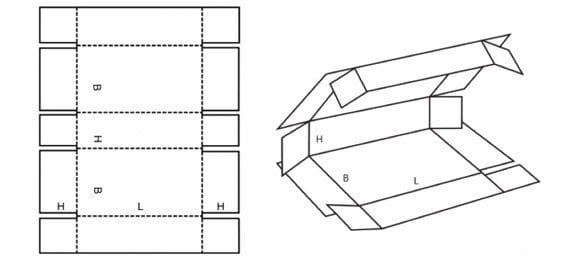

Folding Cartons (Folding Box Board)

Folding Box Board (FBB) is a kind of paperboard made of multiple layers of chemical and mechanical pulp. The top layer consists of bleached chemical pulp with an optional coloured pigment coating for customisation. This lightweight material offers excellent rigidity, printability, and the ability to be shaped into various forms and structures easily.

Kraftpak® board, an unbleached and uncoated high-strength board, can also be used for folding cartons, particularly in food and beverage packaging, due to its ability to withstand moisture and grease. Specialised folding cartons can be created using coloured, metalised, textured, or pearlised boards. The flexibility of this material allows for the production of a wide range of custom boxes, gift packaging and retail cartons.