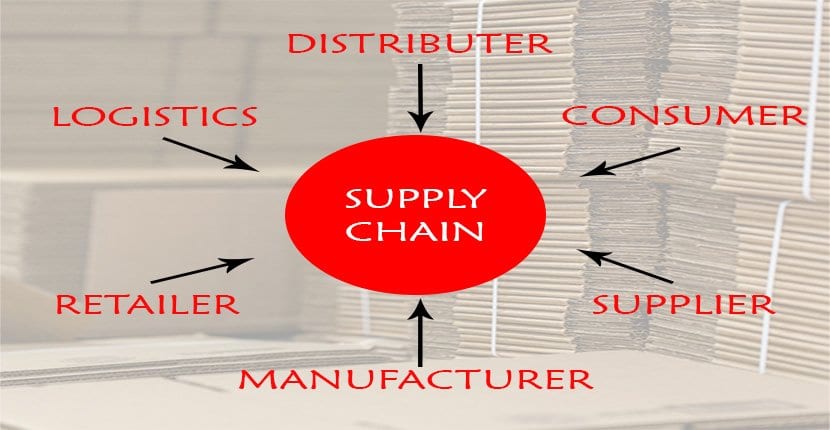

The Role of Packaging in the Supply Chain

Manufacturers and retailers are relying on us; packaging manufacturers and suppliers, for boxes to get essential goods such as food, medicine and medical equipment transported safely across the country during this extraordinary time. Without these boxes the supply chain would not be able to continue.

Packaging Explained

First and foremost, the role of product packaging (i.e. primary, secondary and tertiary packaging) in the supply chain is to protect products from damage during storage and distribution as it moves from the manufacturer to the retailer and eventually onto the consumer. As well as this, packaging also plays an important role in marketing and can be used as a form of communication to consumers to promote products and brands in a competitive market.

Key Packaging Elements for A Continuous Supply Chain:

- Design – This covers many aspects and is important for effective storage, transportation and handling. Ensuring it’s quick and efficient to pack and despatch will reduce time and labour costs.

- Identification – A package that can be easily identified is vital throughout the supply chain. This can include product identification, bar codes or even hazard warnings.

- Optimization – Packaging optimisation will save money, the size of box and materials used will result in less non-essential packaging, lighter distribution costs, less packaging waste and maximised palletised loads.

- Sustainability – Reducing environmental impact by using biodegradable, compostable and recyclable packaging is important now more than ever before.

In short boxes and packaging are essential to the continuation of the supply chain. Good packaging will improve efficiency through this supply chain with well thought out packaging design minimising environmental impact and maximising profits.

To get the most out of your packaging, you must first realise how essential it is.