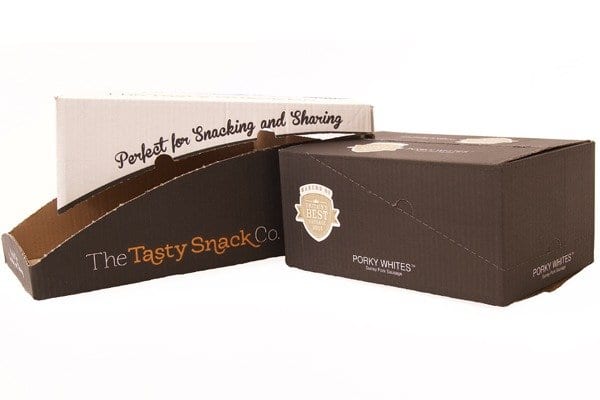

What is Shelf Ready Packaging (SRP) or Retail Ready Packaging (RRP)

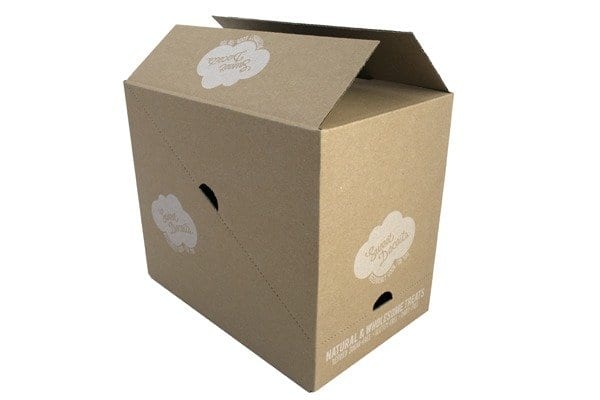

The primary purpose of SRP’s is to ensure that the products they hold are quickly, easily and efficiently placed onto the supermarket or shop shelving display units, without the need for any unpacking, assembly or re-stacking. Shelf ready packaging comes in many designs and covers the entire range of packaging materials found within the retail world.

The secondary purpose of shelf ready or retail ready packaging is to collate and protect your products.

The third purpose of shelf ready or retail ready packaging is to offer the supplier or manufacturer, of the products held within it, the opportunity to promote their brand, advertise their product and interact with the consumer to persuade them to purchase.

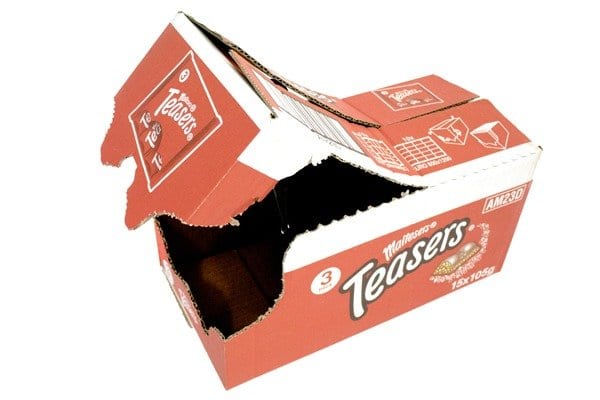

To qualify as SRP or RRP packaging the packs must be:

- Easy to identify

- Easy to open

- Easy to dispose of

- Easy to display on the shelf

- Allow easy access to the products inside

- Easy for stock control within the retail outlet

These elements of SRP or RRP all help to successfully move your products through the supply chain.

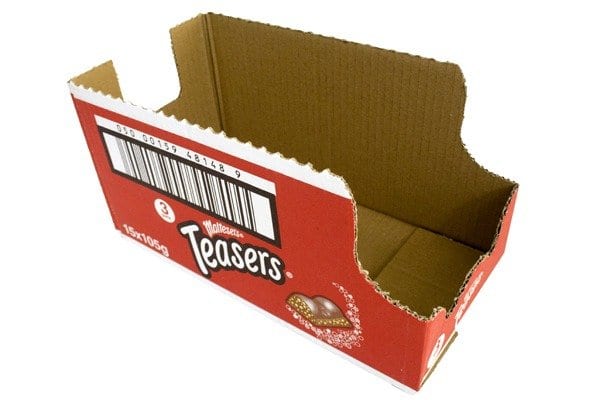

Effects of Good Retail Ready Packaging in store include:

- Good merchandising

- Grow brand recognition and increase consumer communications

- Less risk on new ranges or new product launches

- Product selection made easier

- Faster store replenishment, some leading supermarket won’t accept non SRP/RRP for this reason

- Sophisticated design enables better visibility, less damages and refunded items

- Streamlining the “getting to market” process

- Maximises the amount of product per pallet, which in turn reduces distribution costs as well as reducing the effect on the environment

- Reduction of product storage space required

The Corrugated industry is continually evolving and through clever pack design, artwork and our experience we can help our customers improve their shelf ready or retail ready packaging platform, enhance their brand, raise consumer awareness of their products and reduce their carbon footprint.