Branding is essential for product recognition, brand reinforcement, repeat sales and for getting noticed by those all-important new customers.

It is a well-known fact that people do judge a product by the packaging containing it, therefore it is important to showcase your products’ through good quality printed packaging.

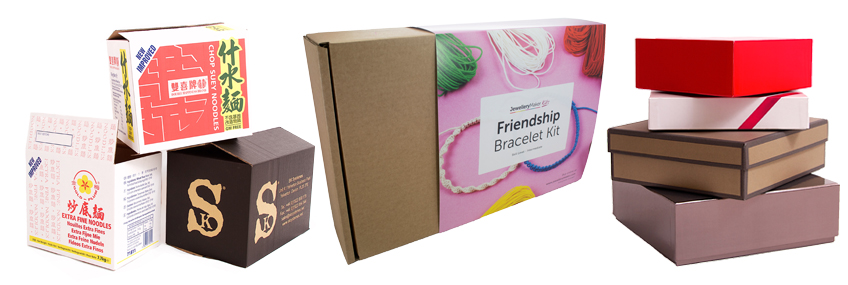

Folding cartons are a single layer board that can be printed

to a very high standard including additional features such as spot UV, high

gloss varnishing, foil blocking and embossing/debossing. Many food products use

folding cartons; they are commonly seen in the refrigeration and freezer

sections of the supermarket and used as either custom printed boxes or sleeves,

which effectively promote the different brands, through printing.

Additionally, folding cartons are used in many other retail

settings, due to the high-quality finishes and printing that can be achieved.

For example, most cosmetics products are made from a folding boxboard, giving a

high-end look to the products.

Corrugated Cardboard Packaging is generally used for the

transit of goods, extremely popular in the food and e-commerce markets. The

corrugated cardboard material offers both protection and the option to print,

therefore identifying the contents of the box and/or promoting your brand at

the same time. Corrugated cardboard packaging can be provided in many

thicknesses of board grade and fluting to achieve the desired level of

protection to the product.

In terms of packaging design, anything from a standard box,

where you tape the top and bottom flaps shut, to a shelf ready retail box,

right through to a custom designed box with bespoke fittings can be produced.

Paper covered rigid boxes are used in the high end, luxury

and gift markets. These boxes are delivered ?made up? and are produced using a

thick sturdy board, giving that expensive feel. We offer a wide range of paper

colours and textures along with foil blocking, embossing and debossing. We can

also print full-colour designs and apply this directly to the rigid box.

Design features such as ribbon pull, and magnetic closures

can be added to further individualize the boxes.

We are lucky to be able to offer an extremely varied choice

of printing techniques, depending on individual budgets and volumes required

and we can advise on the most cost-effective route.

Digitally printed boxes & sleeves: The digital option

has great benefits for multiple print variations or smaller runs. We can

produce exceptional quality from our digital printers and apply gloss or matt

finishes. The shorter lead times and the absence of additional set up costs add

to this being a very attractive option, for start-up companies or those on a

tight deadline.

Flexographic printing:

Mainly used for printing corrugated boxes, the number of colours printed

will depend on the quantity being produced. Large or small runs can be printed

using this method.

Lithographic: This printing style is both suits to folding

carton and corrugated cardboard. The printing quality is superior for clarity

and intricate print design. Options include gold or silver foiling, embossing

or debossing, gloss or matt finishes. Litho laminated boxes are suited more to

higher runs, this keeps the unit costs down which off-set the tooling costs, and

you won?t be disappointed with the result.

Screen printing: The size of the production run would need

to be low or medium in length because silk screen printing is quite a slow

process and not efficient for larger runs. It can, however, produce very sharp,

clean text and images, when used as spot colours. You can also silk screen

print 4 colours process.