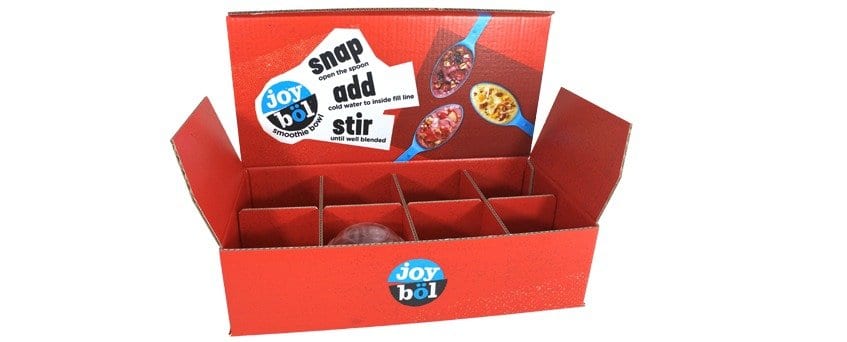

Kellogg’s Joybol packaging Case Study

We produced this study corrugated pack, designed to be used as a sales tool, to promote Kellogg’s new Joybol range of smoothie bowls.

With the deskfasting habit already representing 12% of breakfast occasions and the target audience of urban millennials set to be worth 75% of all packaged food by 2025, Kellogg is on the right track to take advantage of both the trend and the long-term predicted behaviours of busy on the go consumers.

The bold and eye-catching colours used in the branding of the Joybol were screen printed both inside and out, onto this made to measure, corrugated box and divider set to produce a good quality yet visually appealing pack.

So why was Screen Printing the perfect partner for this job?

Our client was looking for a relatively low production run to trial, but they didn’t want to compromise on the print quality, it was important to reflect the brands vibrant colour scheme through its packaging. Because silk screen printing is a slower production process to say litho printing, it was a more efficient process to use than some of the other methods at our disposal and therefore offered the best price to achieve the desired quality. A box like this can also be digitally printed for excellent results but on this occasion, the blank size was too large for that to be an option.

As you can see from the image, silk screen printing was the perfect partner for producing the high- quality imagery and accurate colours required for this particular job. Did you know you can also silk screen print 4 colours process with or without specials?

Packaging Tip;

For the best finish when screen printing onto corrugated, a clay coated board will be used, this will allow for a smoother more even surface to print to. Our team can guide you to the correct combinations of material and print.