A short guide to packaging terms

Whether you are a packaging buyer, a

marketing department, or a new company start up, getting the right

presentational packaging is a huge part of selling your products. This is a

guide to make that process easier and enable you to pick the right materials

and print options.

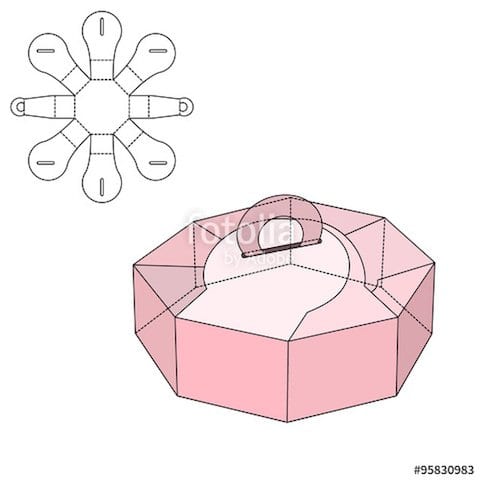

Die cut boxes

à

Designed to fulfill more

exacting requirements. Varying designs can be used to provide special display

features.

à

For example, crash lock bases,

locking tabs, hinged lids, windows and different integral fittings.

à

Depending on whether your

requirement is just for a shipping carton for your product or is more to create

a visual look, this is where the print option variety comes in. Starting with AÎÌøFlexo’

and moving up to AÎÌøLithographic’. (Please see bottom of this blog for help with

printing options)

à

Many of these options can be

suitable for larger presentation boxes.

Carton Board (Folding carton boxes)

à

Carton board which can come in

a variety of different papers depending on what is the required effect for your

product and the necessary strength.

à

Kraft pack for example, is a

material that has become very popular with many online and take-away food

suppliers, giving an authentic and environmentally friendly image.

à

This product can be cut and glued

into over 300 different styles.

à

Special features like adding an

acetate window can be achieved.

à

Lithographic print can be

achieved which can be supplemented with a varnish or gloss/Matt finish.

à

Sleeves are commonly placed on die

cut or standard packaging to aid the point of sale affect.

Presentation boxes (Rigid box)

à

Paper covered rigid boxes for

any high quality products.

à

We have a catalogue of papers

with various texture and colours that can be applied to a rigid box.

à

Made to measure

à

Finishing options include

embossing and foil-blocking.

Print options

Briefly I will take you through the print

options, please look out for our blog next week which will go into more of the details

and benefits of using each of the print options.

à

Flexo (Flexographic) the ink

for the print is applied directly onto the print stereos made from rubber and

this is then transferred on to the printing surface. This process can be used

to print on to paper, cardboard as well as many other materials.

à

Litho printing (lithographic)

is a match made in heaven for high quality volume printing. The image is made

of a polymer coating and applied to an aluminum plate. This style of print is

beneficial when fine detail is required. It can be used with many of the

materials already mentioned and is also very popular with book printing.

à

Digital: Please follow the link to our blog that is

designed to show how your company or department could benefit from digital

printing https://www.pack-supplies.co.uk/blog/159/Get-ready-the-Digital-Evolution-is-Coming

This blog is only a small insight into some

of what can be achieved when trying to personalize/customize or bespoke your

packaging requirements. We hope it

assists you with some of the tricky terminology used within the industry.